What is Metal Plating?

Enamel pins are typically stamped into iron or cast with zinc alloy as a base material, and are then plated with the metal finish of your choice. This involves soaking the pins in a solution that causes a chemical reaction with the metal.

We offer the first 6 enamel colors for free. Your metal plating color doesn't count as a enamel color, but it does need to work well with your design. Make sure you pick a metal color with enough contrast for your enamel colors. For instance, yellow enamel might not stand out as well against gold metal as it would black or silver.

Metal Plating Choices

Shiny Gold

Shiny Silver

Matte Gold

Matte Silver

Antique Gold

Antique Silver

Antique Copper

Rose Gold

Black Nickel

Painted Black

Custom Painted

Rainbow

Differences in Types of Gold Plating

Shiny gold is the most popular type of gold, and is what most people are accustomed to seeing on the vast majority of gold pins.

If you find the standard gold color too shiny but don't want the dulling effect or extra cost of antique metal, matte gold is the perfect solution.

Antique gold is a distressed, vintage-looking finish that is only ideal with a limited amount of designs. Because hard enamel pins need to be ground down upon completion, antique plating is only recommended with soft enamel pins.

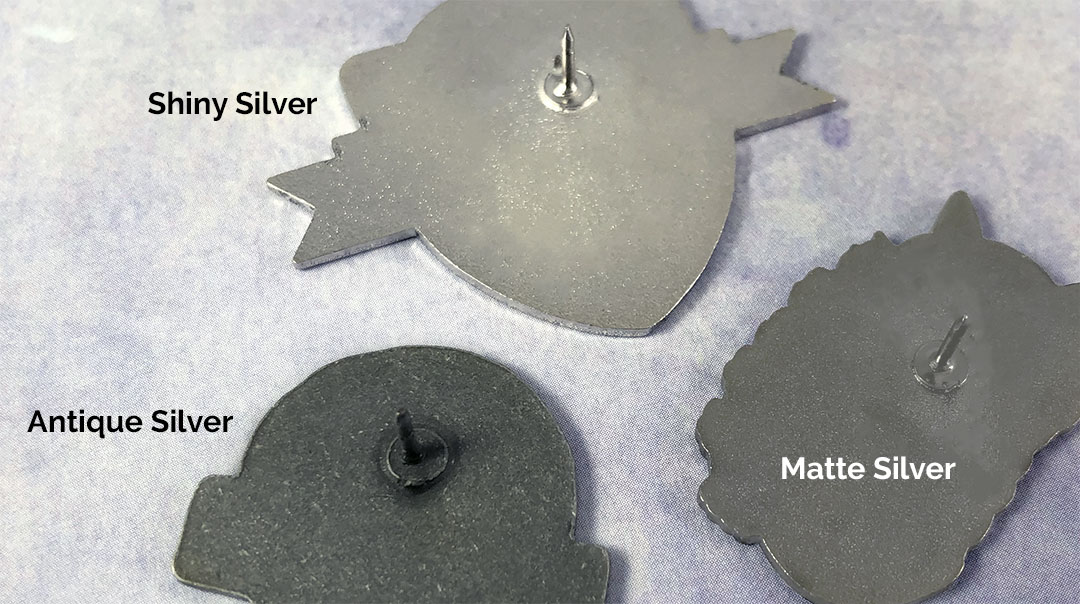

Differences in Types of Silver Plating

Shiny silver is the most popular type of silver, and is what most people are accustomed to seeing on the vast majority of silver pins.

If you find the standard silver color too shiny but don't want the dulling effect or extra cost of antique metal, matte silver is the perfect solution.

Antique silver is a distressed, vintage-looking finish that is only ideal with a limited amount of designs. Because hard enamel pins need to be ground down upon completion, antique plating is only recommended with soft enamel pins.

Get Quote Now!Black Nickel Vs. Painted Black

Black nickel is a very dark gray metal that makes a nice substitute for a true black color. This is commonly used on hard enamel pins, as their metal cannot be painted a true black color.

On soft enamel pins, instead of adding plating you can paint your base metal black to give your pins a true black color. This is not available on hard enamel, because hard enamel pins need to be ground down and polished until they are smooth, which would result in a removal of the black paint.

Get Quote Now!

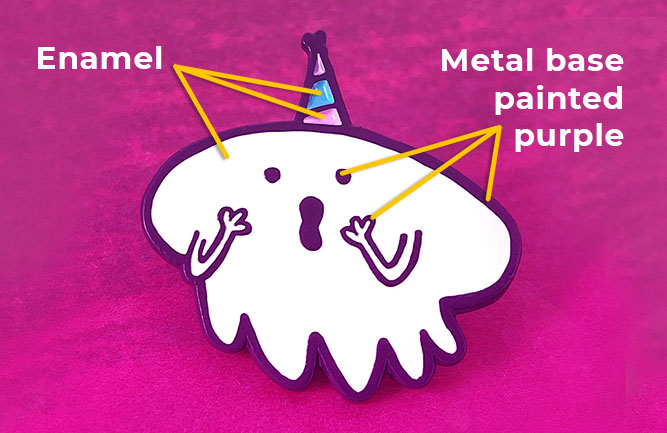

Painted Metal Plating

Sometimes the color pallete you use for your pin design won't be compatable with any of our standard plating colors. If this happens, you can opt to have the plating painted any color you wish.

This process is not available on hard enamel, because hard enamel pins need to be ground down and polished until they are smooth, which would result in a removal of the paint.

Get Quote Now!

A Little About Rose Gold Plating

Rose gold isn't a plating color in and of itself.

To acheive the rose gold look, we will either use a gold-copper alloy with silver mixed in or use a straight copper plating. We base this on which will provide the best final product with the most longevity and least amount of corrosion over time. This is determined by the design, pin process, and pin size.

If you are ordering soft enamel, we recommend putting a layer of epoxy over rose gold pins to prevent corrosion over time.

Get Quote Now!Rainbow Plated Pins

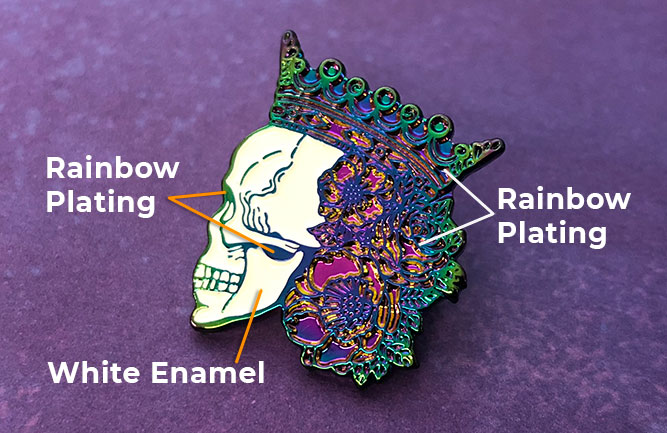

Rainbow plating's incredibly eye-catching and vivid appearance will make your pins stand out from the crowd.

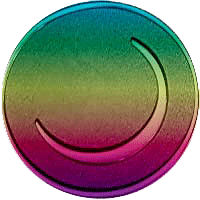

Rainbow-platied pins come in a spectrum of colors that radiate outward. The colors shift and change depending on how long the process is applied to the pin. It will start out blue, then change to yellow, pink, purple, teal, and green. If you order a batch of rainbow pins, expect to see a variety of colors on each individual pin. One pin may be mostly purple and another may end up mostly green. This means that each individual rainbow-plated pin is 100% unique!

Above is the spectrum of colors that you can expect to see on rainbow pins.

The process is called "anodizing"

First, metal pins are cast in a mold, just like any other. Before any enamel is added, the pins are carefully cleaned and prepared for the anodizing process. A chemical solution is created that the pins are submerged into. A grounding wire is then attached to each pin, and an electrical charge is passed through the metal with a wire. The chemical reaction with the electricity creates an amazing rainbow effect on the metal.

This process only needs to be done for a few seconds to change the metal's color. Applying the electricity for even half a second more can drastically alter the color. The final colors are determined by how long the electrical charge passed through them. The pins are then washed of the chemical solution; then the enamel is added, if needed.

Adding enamel is optional

With other types of metal finishes, designers usually pick out a few enamel colors to add to their pin. With rainbow metal, some designers are opting to forgo the enamel altogether. The choice to add enamel or not is entirely up to you. You can add any colors that you'd like but, most commonly, we see rainbow pins with simply black or white enamel added in certain areas. This gives some contrast to the rainbow metal, and is usually used to highlight certain parts of the design.

This process is only available with soft enamel.

Get Quote Now!